Recently added

Related products

Clear coat CP 2015 2K HS 2:1 X-Speed

Most read

Why use the water-soluble lacquers, when the conventional ones are available?

Why is clear coat tested in Florida?

Why is clear coat tested in Florida?

In order to answer that, it is worth recalling a certain story from the past. At the beginning of the car boom, Miami was an automobile transhipment and distribution centre for the whole USA. Often cars spent months on the parking lot, waiting to be loaded onto ships. It was noticed then that some of them showed signs of corrosion which appeared in a short time. Studying these cases, it was noticed that the particular climatic conditions common to this part of the world accelerate the aging of lacquer coatings. For this reason, a plan arose to begin testing of automobile coatings in this very region.

Those times were quite long ago, and quality norms regarding the resistance of clear coats to atmospheric conditions have been strengthened; also many new tests have been devised to help in assessing the influence of external conditions on lacquer over time. However, the best still choose Florida to test clear coat in conditions that are as natural as possible.

The main atmospheric conditions that can cause material degradation are: sun, high temperature and moisture. The most important region in which natural subtropical climate tests are carried out is southern Florida. It is characterised by a rather extreme climate and proximity to the ocean, which allows for the best assessment of the durability of tested materials. The high temperature and high average moisture level through the year are demanding conditions for any lacquer coating.

In comparison, in Poland average rainfall is three times lower than in Florida, and one year of the sun’s effects on the south-eastern coast of America may be compared to a few years of aging in our country.

One year of the sun’s effects in Florida may be compared to a few years of aging in areas with moderate atmospheric conditions.

Exposure to the subtropical climate of southern Florida was conducted for the first time in 1920. It was initiated due to the growing fears of automotive industry representatives, who wanted to obtain a guarantee of the quality and durability of their products.

Which is more harmful – moisture or temperature?

The three main atmospheric conditions that affect clear coat are solar radiation, temperature changes and moisture. They are responsible for undesired material reactions which often cause unnecessary and premature damage to products.

It is not possible to determine which factors have the greatest effect on corrosion of material because various types of solar radiation and various phases of moisture and temperature have an effect on exposed material. These factors, in combination with secondary effects such as air pollution, biological phenomena or the presence of salt, may cause permanent damage to clear coat.

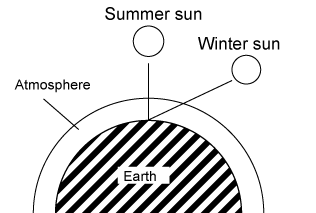

The solar radiation which reaches Earth may be divided into three main groups: UV, visual radiation and infrared radiation. In designing lacquer, it is necessary to ensure resistance to each of the elements of solar radiation. Long-term exposure to solar radiation may affect the quality of a coating as well as the colour of the lacquer.

Temperature, both high as well as low, influences the material tension, which in consequence changes its shape and may cause ruptures in the coating.

Rain, which periodically washes dirt and pollution off the lacquer surface, is at the same time a factor which in the long term accelerates corrosion. Rain drops, falling on a exposed surface that has been heated in the sun’s rays, quickly cool the object, and sudden temperature changes cause material tension which may have dangerous results.

This synergetic influence of UV radiation, temperature and moisture makes Miami the ideal place for testing the durability of materials in natural conditions. The extreme level of sunlight and warm, moist climate is especially suitable for studying changes in colour, loss of colour and gloss, cracking, peeling, blistering and accelerated corrosion.

How is the Florida test carried out?

Exposure methods are specified by automotive norms such as: ASTM G7, ASTM G24, ASTM D143 – which determine direct exposure, as well as ASTM G50, which determine corrosion tests in natural atmospheric conditions.

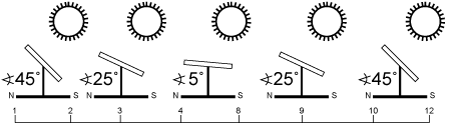

The most important aspects of the test are the technique of assembly and exposure as well as the angle at which the observed product is set.

This has a significant influence on each critical parameter of the test, such as the amount of solar energy, sample temperature or moisture and dampening period. An appropriately chosen exposure angle has the effect of increasing or decreasing the amount of radiation. Each object set outside receives more rays when the sun hits it directly than when the light falls at an angle. In Florida the sun reaches a high zenith; therefore, an exposure sample set at a 5° angle receives more energy than at 45°. In the winter, when the sun is not high at its zenith, it is the opposite – greater energy is received by an object set at an angle of 45°.

In the automotive industry, a 5° effect on the speed at which the tested sample is heated up and cooled. It also influences the time in which the sample is wet from dew or rain. Exposure at an appropriate angle has a direct influence on the reliability of test results.

From April to August a 5° angle is used, in September - 25°, from October to February - 45°, and in March - 25°. The change in angle is designed so as to optimise the solar radiation in each season of the year.

Technical aspects of tests

During the tests, samples are held in frames or on stands, designed so as to not disturb the course of testing and to not cause damage to the observed material. Usually aluminium forms are constructed in a manner that allows easy alterations to the exposure angle of the sample. The assembly method also has an influence on the temperature, which may cause material degradation.

For most materials direct exposure is used, which means that the sample surface is exposed to the effect of the sun’s rays and is not covered.

Why Florida?

Often tests are proposed in climatic, UV or salt chambers. These last a much shorter time and, according to the researchers, give reliable results.

Many tests have been conducted to compare the results of tests carried out in natural conditions with those in laboratories. The comparison makes clear that, while the obtainment of UV radiation of a determined spectrum was similar, other parameters differed considerably.

The industry expects an acceleration in atmospheric research while maintaining high accuracy of data.

The reconciliation of quick sample testing with the maintenance of the reliability of natural conditions remains very difficult to achieve. Therefore, only a small group of companies combine these two types of test. It is complicated and costly – I know about this as every day I make use of these two methods of testing, and I’m convinced that at the present only the combination of various methods allows one to attain certainty in the matter of the quality of tested clear coat. We are fortunate to have the capability of testing samples in our laboratory in Miami.