Recently added

Body Guard: Protection for your Vehicle in Extreme Conditions

Most read

The most popular

Waterbase coat system Aqua 2G 1K

Improving the Curing Process: Changing Profix hardeners for better quality and efficiency

Improving the Curing Process: Changing Profix hardeners for better quality and efficiency

In an effort to simplify the product selection process while ensuring expected quality and efficiency, we are making changes to our range of hardeners. These changes aim to standardise on one set of hardeners, reducing the risk of variability in the curing process.

Here are the details of the changes.

The following product groups will be able to use the new set of hardeners:

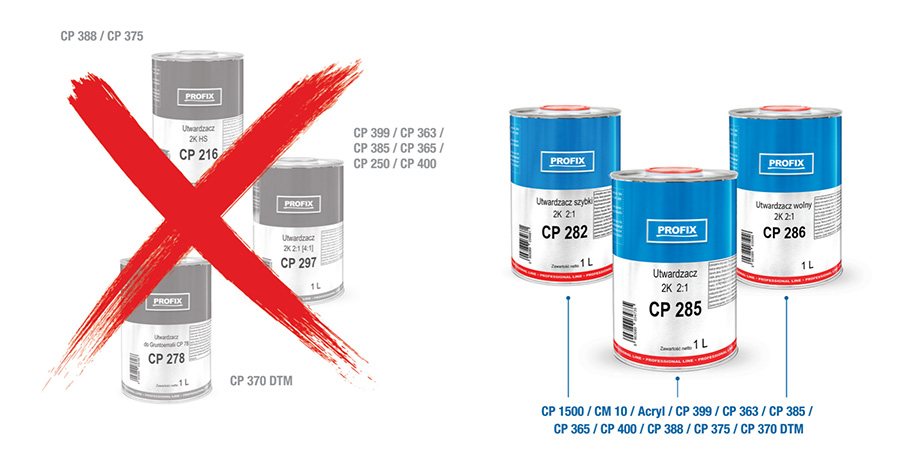

- CP 399, CP 363, CP 385, CP 365, CP 250, CP 400 products, which previously used CP 297

- Products CP 388, CP 375, which previously used CP 216

- Products CP 370 DTM, which used CP 278

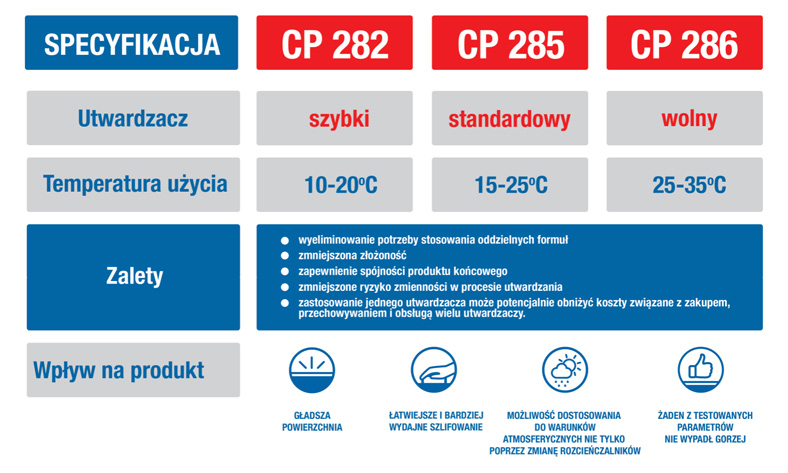

We are therefore introducing CP 282, CP 285 and CP 286 hardeners, which have specific temperature ranges for optimum performance. This will allow better adaptation to weathering conditions:

CP 282 (Fast Hardener) for temperatures of 10-20℃.

CP 285 (Standard hardener) for 15-25℃.

CP 286 (Slow hardener) for 25-35℃.

These hardeners will not only be compatible with the products that replace the previous solutions, but also with our products such as CP 1500, CM 10 and Acrylic, allowing for even better customisation.

It is hoped that these changes will simplify the purchasing, storage and handling process, reducing the cost of managing a number of different hardeners and improving resource management efficiency.

New capacities for the CP 28X family will also be introduced, increasing convenience and flexibility. The changes will be implemented on a permanent basis from late June/early July.